Ringlock Scaffolding: A Reliable Choice for Modern Construction Sites

I’ve been in the construction industry for over 15 years, and I’ve worked with all kinds of scaffolding systems – from traditional frame scaffolding to the more advanced ringlock scaffolding. The shift has been huge, especially as projects get taller and more complex. These days, when safety and efficiency are non-negotiable, choosing the right ringlock scaffolding manufacturer can make all the difference on a job site.

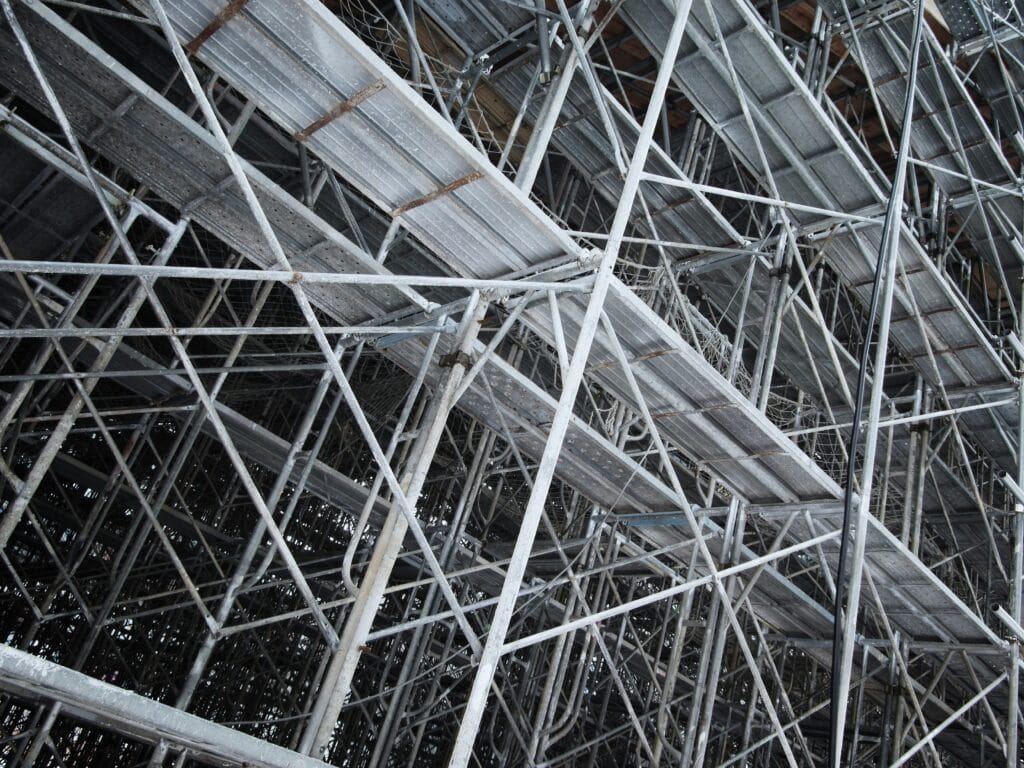

My first real experience with ringlock scaffolding was on a high-rise residential project a few years back. We started with old-school frame scaffolding, but it was slow to erect, had too many loose parts, and honestly, it felt risky in windy conditions. Switching to a ringlock system changed everything. Assembly was faster, the structure felt rock-solid, and the crew was happier knowing it was safer.

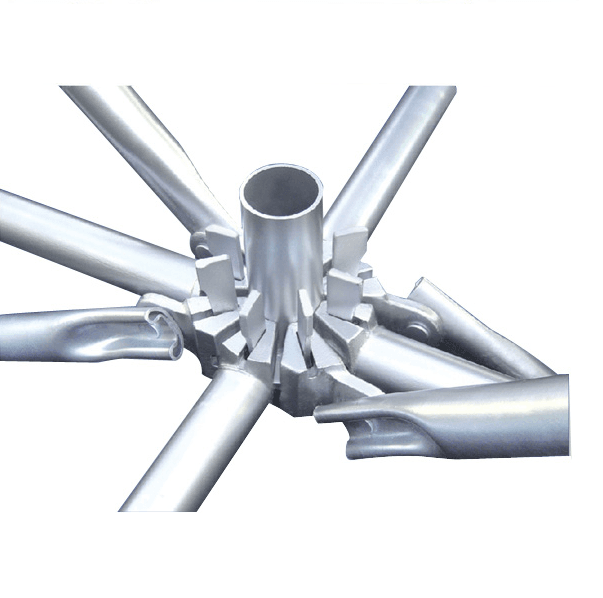

At its core, ringlock scaffolding (also called rosette scaffolding) uses vertical standards with rosette nodes every 0.5 meters. Horizontal ledgers and diagonals connect with wedges that lock in place with a simple hammer tap – no bolts, no fuss.

This design provides incredible load-bearing capacity, making it ideal for heavy-duty applications like bridges, industrial maintenance, or even shipbuilding.

Here are some key advantages I’ve seen firsthand as a ringlock scaffolding supplier would highlight:

Superior Strength and Stability: The rosette connection distributes weight evenly, handling heavier loads than traditional frame scaffolding or steel props.

Quick Assembly and Dismantling: Workers can erect it 3-5 times faster – just align, insert, and hammer. Perfect for tight deadlines.

Enhanced Safety: Built-in guardrails and anti-slip platforms reduce fall risks. Plus, the wedge lock prevents accidental disconnection.

When selecting a ringlock scaffolding manufacturer, look for ones using high-quality Q235 or Q355 steel, hot-dip galvanized for rust resistance. As a China-based scaffolding manufacturer, many factories now offer customized systems, including aluminum options for lighter weight.

A few safety tips from the field: Always inspect rosettes for wear, use base jacks for leveling, and follow load limits strictly.

In my experience, investing in a good ringlock scaffolding setup pays off in fewer accidents and faster project completion.

If you’re sourcing ringlock scaffolding for your next job, prioritize certified suppliers with proven track records. It’s not just equipment – it’s about keeping your team safe and productive. What’s your experience with different scaffolding types? Feel free to share!

Welcome to www.mavixscaffolding.com